“Eligimus Dura” - We Choose the Hard Path

UCI Rocket Project Liquids Team

About the Project

The UCI Rocket Project Liquids Team is an extremely competitive aerospace engineering team of over 40 students at University of California Irvine, working on complex propulsion, aerodynamic, and ejection systems. These systems follow stages of professional modeling and simulation software, innovative manufacturing, fabrication solutions, and strict validation procedures.

As a team solely comprised of undergraduate students, we aim to break the collegiate methalox altitude record of 13,205 feet while reducing our cycle time from 6 years down to 2 years. We are currently working on our next rocket, MOCH4 (catchy acronym for the methane and oxygen propulsion system used), for our upcoming launch in Spring 2025.

To the right, you can find the official video of our first launch in April 2023 with detailed interviews and footage of our ground-breaking success.

Propulsion Engineering

Leading up to launch, many preparatory tasks have been assigned to me, primarily machining, formulating ignitors for testing, and upkeeping documents. Being a vital part of the final steps to launch is a big responsibility and by giving high effort to CDR’s, quality testing, and thorough contribution, I hope to set our project up for further success.

Timelapse video of me and other teammates using RTV to seal ablative material and a nozzle to our welded engine before a vertical test fire last winter

-

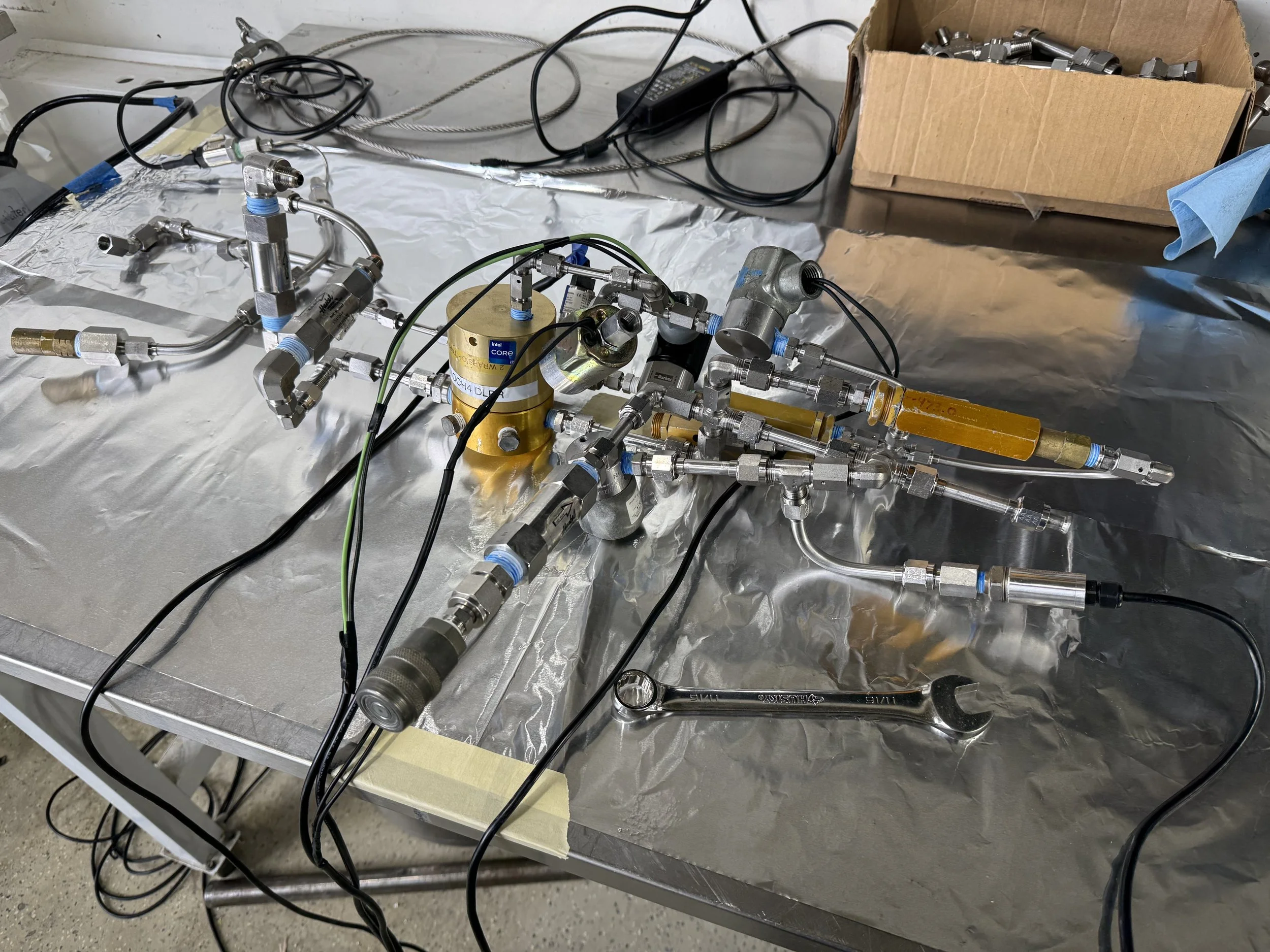

Much of my role as a propulsion engineer is ensuring that FOD is removed from the system by disassembling the feed lines and fittings on the rocket, cleaning them and spraying them with IPA before putting them back together.

I also assist with cold curing and formulate our own ignitors for our combustion chamber using PBAN, aluminum, epoxy, and hardener, two weeks prior to travelling out to the desert to conduct testing.

-

When the critical step of filling our tanks with propellant takes place during Cold Flow and hot fire testing, my role as dewar operator requires me to pressurize the dewar as needed and properly vent, close, and open fill lines as we prechill and fill our system.

I monitor proper psi levels and amount of cryogen flowing into the tanks, until a 10 minute timer is up after starting fill or liquid begins spewing out of the vents of the rocket.

-

Due to complications with melting and potential oxidation of our injector, I helped redesign part geometry for critical design reviews and manufacturing over this summer, resizing O-ring grooves for leak-resistant sealing according to the Parker O-ring handbook. I have completed drawings of the injector for CNC machinists.

I conducted oxidation research to decide on C101 as a replacement material for our injector faceplate, as the tensile strength and melting point of the metal is much higher than the previous selected material of aluminum that our project has used for years.

-

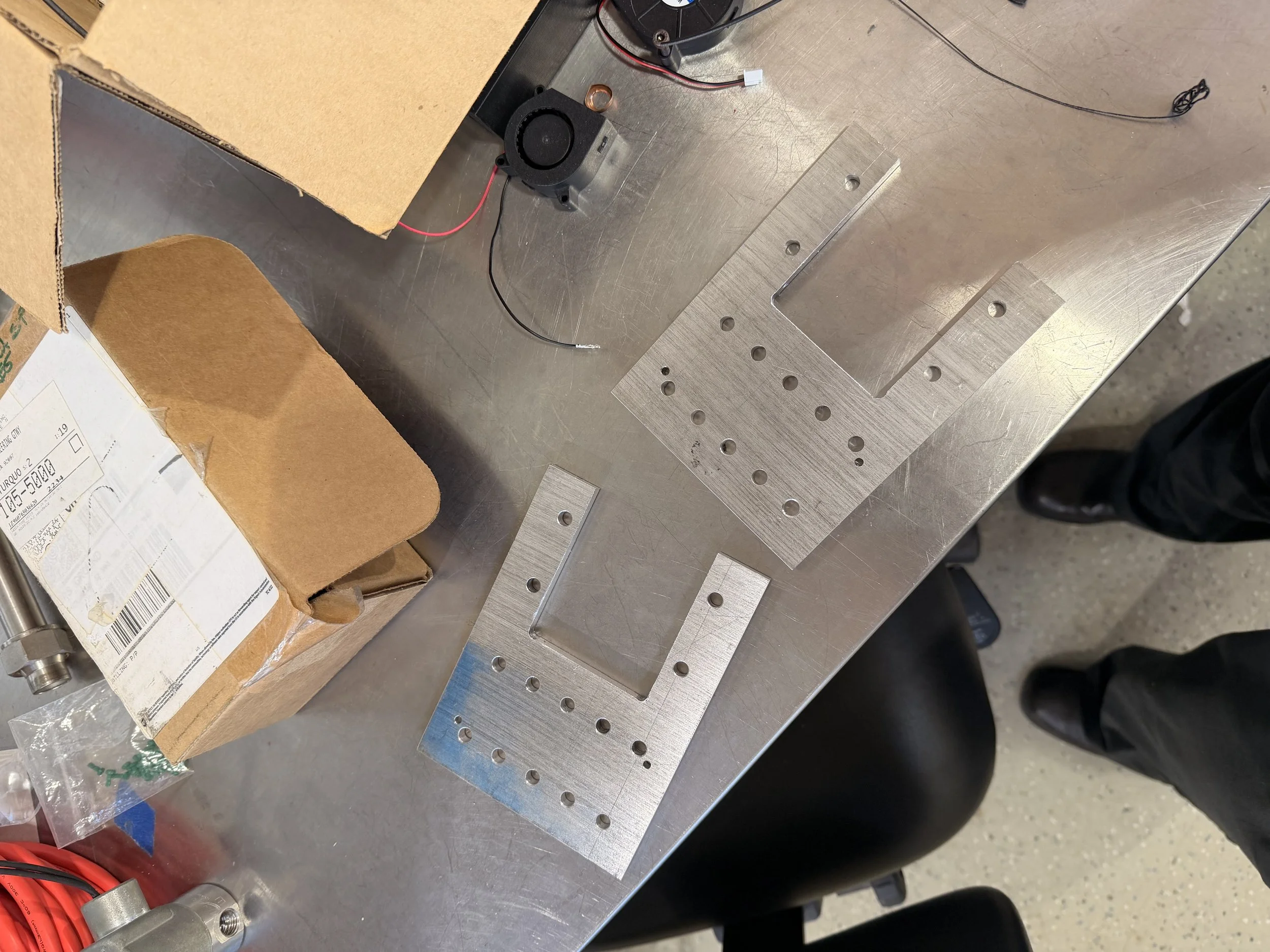

I machined and bent mount brackets for the pneumatic actuation system, intended to separate from the rocket pre-flight to reduce mass.

Mounted externally from our rocket, the machined components attach onto the pneumatic valve, and once actuated and opened, the valve turns 90 degrees into a position where it can slide through a built-in slot to detach from the rocket once combustion begins and it takes off.

You can view the machined brackets and mounts I made on the Lathe and Mill page of my website.

-

Throughout this summer, I created a JIC/AN/NPT/Compression fitting manual and annotated our feed system Piping and Instrumentation Diagram for team cohesion.

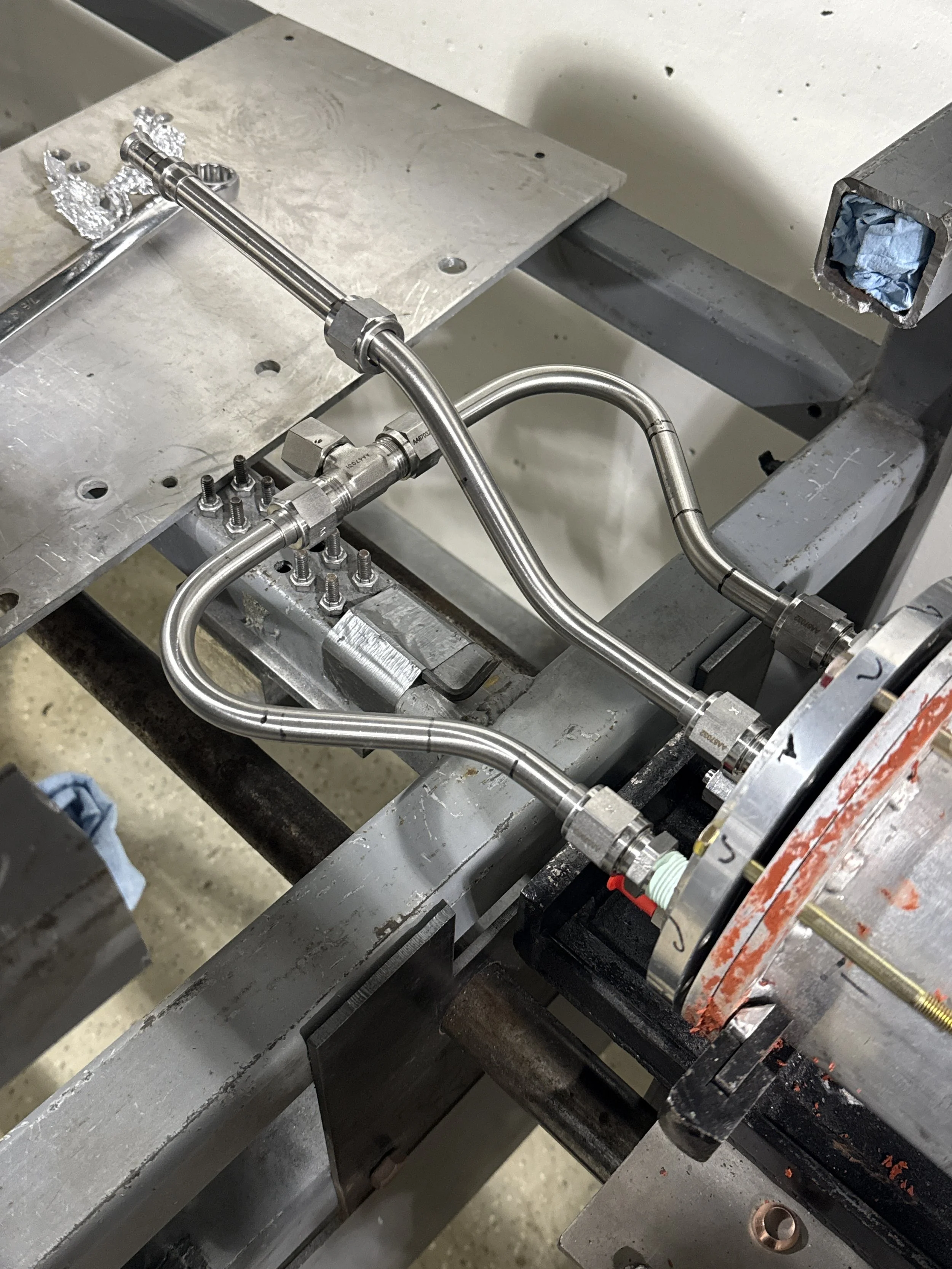

In House Manufacturing of MVAS MountsMy triplet impinging redesign drawingsIgniter Retention Mechanism Intended to interface with Engine flange at Engine chamber ExitP&ID and Fitting GuideSystem Disassembly and CleaningIgnitor MixingIgnitor Being Used in VTF #2Ignitor Being Used in VTF #2Bent and Flared tubing to mitigate leakage to injector portsEngine Nozzle IntegrationDewar Operating Footage

Applications Engineering

Cold Flow Documentation Template Created By Me

-

My position as Applications Engineer consists of building partnerships with industry professionals and companies by attending industry-related events/conferences, working with our subteam leads to implement CADed rocket parts, and completing thorough research to locate needed materials for our project.

Last year, 2024-2025, I accumulated over $17k of donated parts from companies for the team, including engine nozzles, rocket stringers, bulkheads, and PCBs. -

During Cold Flows, weekly tests of our rocket MOCH4’s propellant flow simulated with liquid nitrogen, my duty as Documentation Officer was to keep logs of crucial data such as tank pressure leakages and LN2 fill times.

To keep documentation organized, I created a template for official cold flow timelines for the project. Within these documents, important notices and timestamps are logged to keep track of team progress as we proceed to do more tests and procedures on our rocket leading up to launch.

-

Throughout my fall quarter at UCI 2024, I made it a priority to help out with any other Operations-related tasks with my subteam leads. This includes:

Redesigning the Project CRM, which lists all company relationship standings within the project

Engine-nozzle integration with Propulsion team members

Assisted with project manufacturing timeline as well as a rocket component data spreadsheet to analyze the total mass of our rocket

More Photos from Networking Conferences

Bulkheads and Stringers I got donated

Stringers from TJ AerospaceBulkheads from Bel Air Machining